Fluorescent Penetrant Inspection

Liquid Penetrant Testing (Fluorescent Penetrant Inspection – FPI) is one of the many testing procedures available through Loos Precision Products. This process is a form of non-destructive testing (NDT) that checks for machining defects without deforming, marring, or otherwise damaging a finished product. While liquid penetrant testing is most commonly used to analyze medical products and aerospace components, it can be implemented for virtually any industry’s hardware, and is always performed according to ASTM E1417 standards. Have questions about our products or services? Do not hesitate to contact our knowledgeable sales team today.

How Liquid Penetrant Testing Works

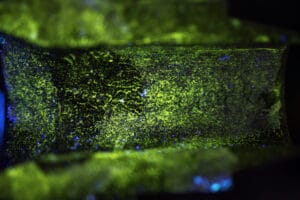

Liquid Penetrant Inspection detects imperfections that may have been created throughout grinding, machining, or forging processes. A fluorescent chemical is applied to the product’s surface, thus settling into cracks or other textured areas. Because the solution glows under ultraviolet (UV) light, it creates vivid contrast between the smooth surface and rough imperfections, making it easy to detect irregularities. While marks are just harmless cosmetic flaws, others may impact the overall performance or structural strength of the finished components, which is why inspection at this stage is so important.

Common Flaws Detected:

- Cosmetic defects

- Cracks

- Irregularities

- Porosity

- Seams

- Surface roughness

The Benefits of Fluorescent Penetrant Inspection

This inspection process does not harm the components being inspected, due to its non-destructive testing nature. It is an efficient way to inspect a large quantity of parts or materials with a high level of accuracy, as it can detect smaller defects such as hairline cracks. You can implement your components with confidence knowing they are free from even the smallest defects and functioning at the highest level of performance.

- Identifies even small surface irregularities and issues

- Allows parts components of almost any shape or size to be inspected

- Can be used on most nonporous materials