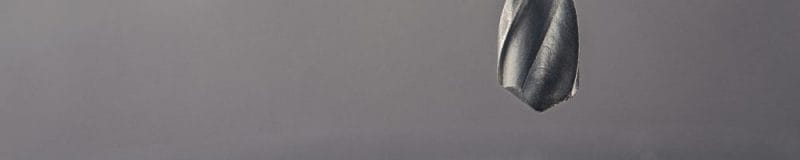

Stainless Steel

Stainless steel is one of the most common materials used in custom machining because it is versatile, corrosion resistant, and available in a wide selection of grades. Here at Loos Precision Products, we have the skill and technology to produce unique hardware and components according to your exacting specifications. Learn about a selection of industries and applications that rely on the physical proprieties of stainless steel below. As always, do not hesitate to contact our skilled craftsmen with any questions about our materials or machining process.

Industries and Applications

316 stainless steel is commonly used to create hardware and fasteners in aerospace industries and applications. It is a very popular alloy that resists corrosion and heat, similar to 304 stainless steel. It is nonmagnetic, making it ideal, and it offers even greater resistance to corrosive agents than other 300 series steels. 304 steel is also nonmagnetic, and it offers excellent corrosion resistance against heat and oxidation.

- Aerospace components

- Hardware

- Fasteners

- Nuts and bolts

- Aerospace

- Medical

- General Industrial

- Engineering

Loos Precision Products has the capability to produce intricate parts with the help of our advanced lineup of machinery. Whether you need lightweight fasteners for aerospace applications, or durable valves for marine equipment, we have the experience required to get you the exact product you need. Have questions about our materials or machining processes? Request a service quotation below or submit a request for product consultation. Our knowledgeable machinists are happy to help address any of your inquiries.